Single turbines are simpler and more compact, making them easier to maintain, but they might struggle with high-capacity or demanding vacuum needs. Twin turbines, however, offer better efficiency and reliability under heavy operational conditions by sharing the workload. They are more complex and may require more upkeep. Choosing between them depends on your specific process requirements—continue exploring to discover which technology fits your application best and the latest advancements in their design.

Key Takeaways

- Single turbines are more compact and simpler, ideal for moderate vacuum needs, while twin turbines offer higher efficiency for demanding applications.

- Twin turbines provide better vacuum performance and energy efficiency by sharing workload, unlike single turbines with limited high-capacity capacity.

- Maintenance is generally easier and less frequent with single turbines due to fewer components, whereas twin turbines require more upkeep.

- Twin turbines are suited for high-capacity, high-vacuum environments, offering greater reliability at the cost of increased complexity.

- Technological advancements aim to improve both, but the choice depends on specific process requirements and long-term operational considerations.

When choosing suction technology for industrial applications, understanding the differences between single and twin turbines is essential. Both options serve critical roles in processes that demand reliable vacuum generation, but they differ substantially in how they perform and what they require for upkeep. Your decision should consider factors like vacuum efficiency, maintenance requirements, and overall operational needs to ensure ideal performance and cost-effectiveness.

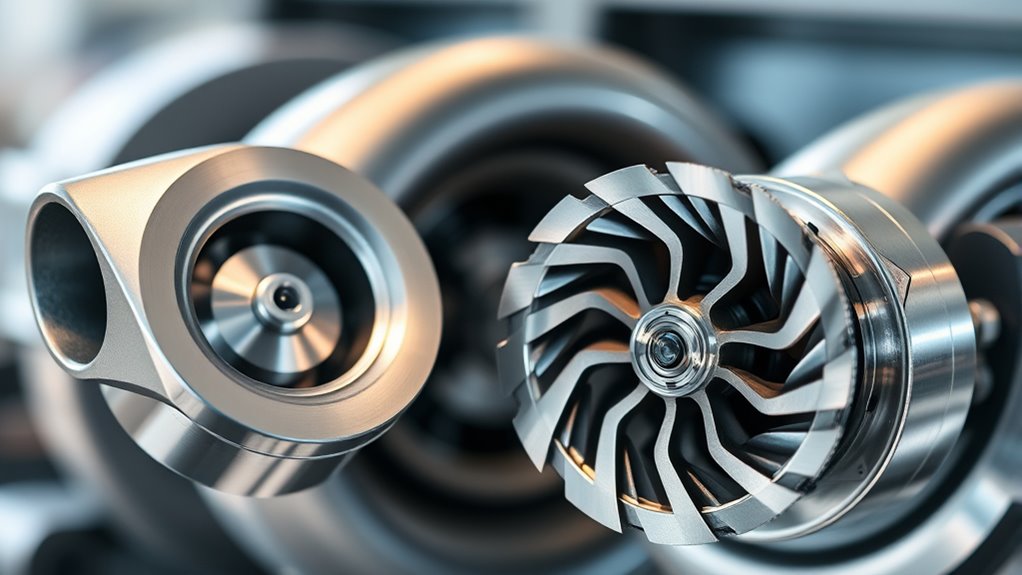

Single turbines are straightforward and often favored for their simplicity. They typically consist of one turbine motor that drives the vacuum pump. This design tends to be more compact and less complex, which generally translates into easier maintenance. Since there are fewer moving parts, the likelihood of mechanical failure is reduced, and maintenance requirements are often lower. However, because they rely on a single turbine, their vacuum efficiency can be limited at higher throughput levels. If your application demands a consistent, high-volume vacuum, a single turbine might struggle to keep up, resulting in potential drops in performance or longer cycle times.

Twin turbines, on the other hand, incorporate two turbines working in tandem. This configuration can greatly enhance vacuum efficiency, especially in demanding industrial settings where maximum suction power is necessary. With dual turbines sharing the workload, they can maintain higher vacuum levels more reliably and with greater stability. This setup often leads to increased energy efficiency, as the load is distributed more evenly, reducing strain on each turbine. However, the trade-off is that twin turbines typically involve more complex machinery, which can lead to increased maintenance requirements. The additional components mean more potential points of failure, and the need for regular inspections and upkeep can be higher. Maintenance intervals might be shorter, and repairs could be more involved and costly.

Your choice depends greatly on your specific operational demands. If your application involves moderate vacuum needs and values simplicity and ease of maintenance, a single turbine system might be the best choice. Conversely, if you require high vacuum efficiency, reliability at high capacities, and are prepared for more regular maintenance, twin turbines could be more suitable. Consider factors like long-term operational costs, downtime, and potential upgrades when making your decision. Additionally, advancements in turbine technology continue to improve performance and reduce maintenance burdens, making it worth staying informed about the latest developments. Ultimately, understanding how each technology aligns with your process requirements will help you select the most effective and efficient suction system for your industrial needs.

Frequently Asked Questions

How Do Maintenance Costs Differ Between Single and Twin Turbine Suction Systems?

You’ll find that twin turbine suction systems generally have higher maintenance costs due to their increased complexity, but they offer better cost efficiency over time because of improved operational durability. Single turbine systems are simpler and cheaper to maintain initially, but they might need more frequent repairs, which can add up. So, your choice depends on balancing upfront costs with long-term reliability and operational savings.

Which Turbine Configuration Offers Better Performance in Variable Sea Conditions?

You’ll find that twin turbines generally offer better performance in variable sea conditions because they handle fluctuating pressures more efficiently. This resilience benefits marine biodiversity by maintaining stable operations that minimize environmental impact. Plus, their superior corrosion resistance ensures durability in harsh environments, reducing maintenance disruptions. As a result, twin turbines enable more reliable, eco-friendly performance, especially when steering through unpredictable marine environments, safeguarding marine biodiversity while maximizing operational efficiency.

Are There Significant Safety Concerns Unique to Twin Turbine Setups?

You should be aware that twin turbine setups present unique safety concerns, primarily related to hazard identification. These systems involve more complex machinery, increasing the risk of mechanical failures or leaks. To mitigate these risks, it is crucial to follow strict safety protocols, perform regular inspections, and guarantee proper training. Doing so helps prevent accidents, maintains system integrity, and promotes safe operation in challenging sea conditions.

How Does the Installation Complexity Compare Between Single and Twin Turbines?

You’ll find that twin turbines generally have higher installation complexity compared to single turbines. They require more extensive structural integration, including reinforced mounting points and additional support systems, which can make setup more time-consuming. In contrast, single turbines are simpler to install, often fitting into existing structures with fewer modifications. If you’re considering installation, weigh the benefits of increased capacity against the added structural and logistical challenges of twin turbine systems.

What Are the Environmental Impacts of Each Suction Technology?

You should consider how each suction technology impacts marine biodiversity and energy consumption. Twin turbines often consume more energy, which can lead to greater disruption of marine ecosystems if not managed properly. Single turbines tend to be more energy-efficient, reducing environmental stress and preserving marine biodiversity. Your choice affects the ecosystem, so prioritize technologies that minimize energy use and protect marine life while maintaining effective operation.

Conclusion

Just like the legendary duel of Hercules and the Hydra, choosing between single and twin turbines depends on your strength and needs. Single turbines offer simplicity and efficiency, while twin turbines provide power and redundancy. Think of it as a battle of the gods—each has its own might. Ultimately, your decision shapes your journey, so weigh your options carefully. Remember, whether you wield one or two, your success is the true victory in this technological myth.