Docks recognize different robot models by examining their visual features, such as shapes, sizes, colors, and markings, along with hardware indicators like sensor placements, ports, antennas, and physical design elements. They also use software cues, including model labels and system IDs displayed on interfaces or diagnostics. These combined identifiers help guarantee accurate task assignment and efficient management. If you keep exploring, you’ll discover even more detailed ways docks distinguish various robot models.

Key Takeaways

- Visual identification through distinct shapes, colors, and markings on each robot model.

- Hardware features such as sensor placement, port locations, and antenna designs unique to models.

- Software interfaces displaying model information like labels, firmware versions, or system IDs.

- Use of reference guides or databases for quick cross-checking of physical and software cues.

- Recognition of specialized sensors and hardware configurations that differentiate robot types.

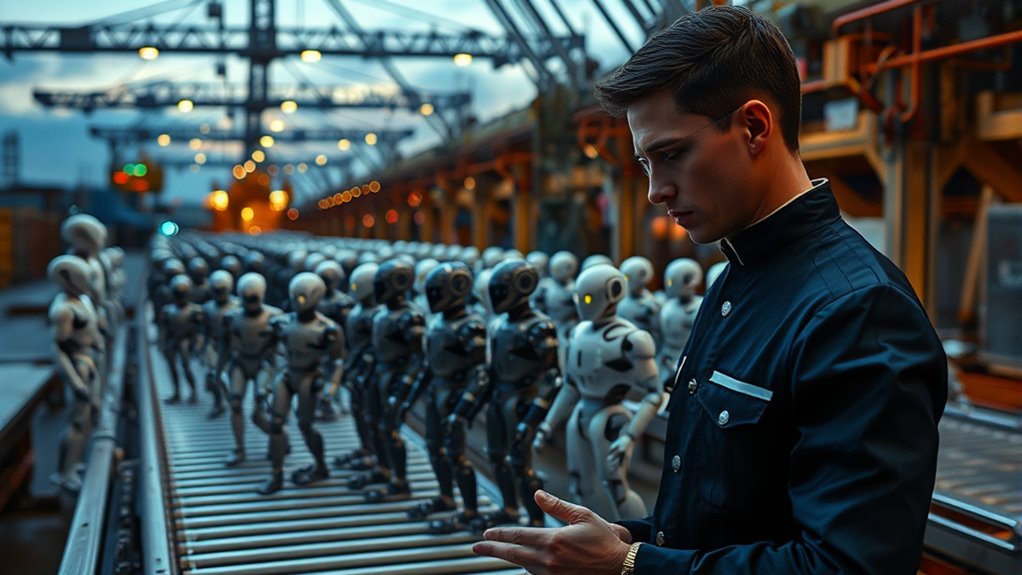

Recognizing different robot models is essential for understanding their capabilities and applications. When you’re working with various robots in a dock environment, being able to quickly identify each model ensures smooth operations and efficient management. This process, known as robot identification, relies on distinguishing features that set one model apart from another. Model differentiation helps you understand which robots are best suited for specific tasks, whether it’s transportation, inspection, or maintenance. Your goal is to learn the key identifiers that allow you to recognize each robot’s model at a glance.

Quickly identify robot models to ensure smooth operations and effective management in dock environments.

To achieve effective robot identification, you should pay attention to physical characteristics. Many robots have distinct shapes, sizes, and designs that can give you immediate clues about their model. For example, some might have a compact, boxy frame, while others feature elongated arms or specialized sensors. Look for noticeable differences in color schemes, branding, or markings that are often unique to each manufacturer or model. These visual cues make it easier to differentiate models during quick inspections or when managing multiple units simultaneously.

Beyond appearance, many robots come equipped with specific hardware components that serve as identifiers. Cameras, lidar sensors, or other sensing equipment are often positioned differently depending on the model. Recognizing these sensor placements can help you quickly determine the robot’s type, especially in environments where multiple models operate side by side. Additionally, some models have unique ports, antennas, or antenna placements that further aid in identification. Familiarity with these hardware distinctions allows you to differentiate models without needing to access detailed specifications.

Software indicators also play a vital role in robot recognition. Many robots display model information on their user interfaces or through diagnostic systems. When you access a robot’s control panel or interface, look for labels, firmware versions, or system IDs that specify the model. This information confirms your visual assessments and helps you differentiate between closely related models. Keeping a reference guide or database of known models and their identifying features can streamline this process and reduce errors.

Understanding model differentiation isn’t just about identification; it’s about optimizing your management of the fleet. When you know which robot is which, you can assign tasks more effectively, troubleshoot issues faster, and ensure that maintenance routines are properly tailored to each model’s requirements. In a busy dock environment, this knowledge minimizes downtime and maximizes productivity. Recognizing Glycolic Acid Benefits and the various features associated with different models can further enhance your ability to manage and utilize your robot fleet effectively.

Frequently Asked Questions

Can Docks Identify Custom or Modified Robot Models?

Yes, docks can identify custom or modified robot models if they have unique visual markers or are compatible with the firmware. You should guarantee your robot’s visual marker is distinct so the dock can recognize it easily. Additionally, firmware compatibility is essential; if your modifications maintain compatibility, the dock can still identify and communicate with your robot effectively, even if it’s customized.

How Do Docks Differentiate Between Similar Robot Brands?

You can tell similar robot brands apart through visual recognition, which identifies unique design features or markings. Docks also use firmware updates to stay current with brand-specific software, helping them distinguish between models with subtle differences. When a robot docks, it scans for these visual cues and checks firmware versions, ensuring it correctly recognizes the brand and model, even among similar-looking robots.

Are There Limitations to Recognizing Older Robot Models?

Think of recognizing older robot models like trying to read an ancient map with fading ink. Visual recognition struggles with outdated images, and hardware limitations can hinder the dock’s ability to process new data. As technology advances, older models may lack the distinct features current systems rely on, making recognition less reliable. So, yes, there are limits, especially when the dock’s hardware isn’t equipped to handle the nuances of vintage robots.

What Role Does Software Updates Play in Recognition Accuracy?

Software updates considerably improve recognition accuracy by enhancing software compatibility and refining recognition algorithms. When you update the dock’s software, it can better identify new or evolving robot models, reducing errors. These updates often include improvements that adapt to changing robot designs, ensuring the recognition system stays current. Regularly updating your system helps maintain ideal performance, making it easier for the dock to accurately recognize different robot models over time.

Can Docks Recognize Robots Without Visual Identifiers?

Yes, docks can recognize robots without visual markers, acting like a detective following clues. They rely on advanced sensor technology, such as infrared or ultrasonic sensors, to detect unique physical traits or movement patterns. These sensors help identify robots even in low-light or cluttered environments. So, even if visual markers are absent, your robot’s unique signals and the dock’s smart sensors work together, ensuring smooth recognition and seamless operation.

Conclusion

So, next time you think identifying robot models is a simple task, remember—docks can distinguish them with ease, while you’re left puzzled. It’s ironic how these machines, designed to serve us, effortlessly recognize their own kind, yet we struggle to tell them apart. Maybe it’s time to admit that even in a world of advanced tech, some things are still easier for the robots than for us. After all, they’re the true experts in their own kind.