Self-cleaning brush assemblies in docks work by using rotating or oscillating brushes to remove debris, algae, and biofouling automatically from surface areas. They operate continuously, reducing manual cleaning efforts while preventing buildup that can cause corrosion or damage. Made from durable, corrosion-resistant materials, these systems guarantee long-term effectiveness even in harsh marine environments. If you keep exploring, you’ll discover how these systems enhance dock longevity and reduce maintenance costs.

Key Takeaways

- They use rotating or oscillating brushes to dislodge debris, algae, and biofouling from dock surfaces automatically.

- Made from corrosion-resistant materials like stainless steel or plastics to withstand harsh marine environments.

- Operate continuously without manual intervention, ensuring consistent cleaning regardless of weather or personnel presence.

- Help prevent corrosion and structural deterioration by removing buildup that promotes rust and damage.

- Support long-term dock maintenance by reducing manual cleaning efforts and extending the lifespan of dock components.

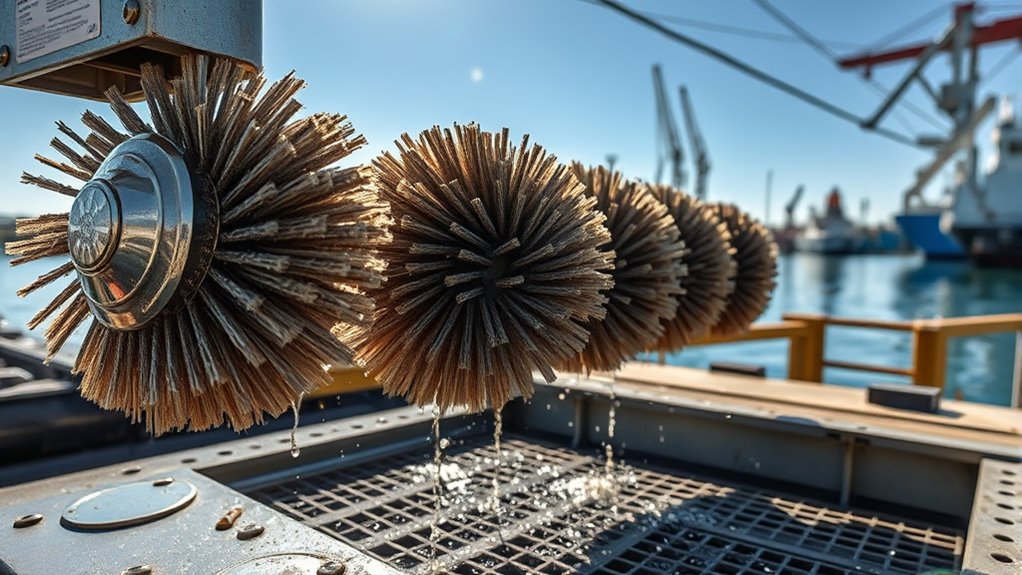

Self-cleaning brush assemblies in docks are innovative solutions designed to reduce maintenance and improve efficiency. When you’re managing a dock, one of the biggest challenges you face is dealing with marine corrosion and the constant need for dock maintenance. Marine environments are harsh, filled with saltwater, humidity, and biological growth, all of which accelerate corrosion on metal structures and other materials. Traditional cleaning methods can be labor-intensive and often require frequent attention to prevent deterioration. That’s where self-cleaning brush assemblies come in, offering a proactive approach to keeping docks clean and functional with less effort on your part.

These assemblies work by utilizing specially designed brushes that automatically remove debris, algae, and biofouling from the dock’s surfaces. As the system operates, the brushes rotate or oscillate, dislodging buildup that could otherwise promote corrosion or hinder dock performance. This continuous cleaning process helps prevent the accumulation of grime and biological matter that often leads to corrosion, especially on metal components exposed to seawater. By reducing the amount of debris and biofouling, the assemblies also minimize the need for manual cleaning, which is often time-consuming and costly.

One of the key advantages of self-cleaning brush assemblies is their ability to maintain the integrity of the dock’s structure over time. Marine corrosion can weaken supports, pilings, and other critical infrastructure if left unchecked. Regular, automated cleaning means you catch corrosion issues early, preventing costly repairs and prolonging the lifespan of your dock. Additionally, these systems are designed to be durable and resistant to the corrosive marine environment itself, often constructed from corrosion-resistant materials like stainless steel or specialized plastics. This resilience ensures that the brush assemblies remain effective over extended periods, even in the most challenging conditions.

Furthermore, self-cleaning brush assemblies contribute to overall dock maintenance by reducing the frequency of manual interventions. You won’t need to schedule as many inspections or cleaning crews, saving both time and money. The system’s automation also ensures consistent cleaning, unlike manual methods that can vary depending on personnel and weather conditions. As a result, you create a safer, cleaner environment for vessels and personnel, while also protecting your investment from the damaging effects of marine corrosion. Incorporating corrosion-resistant materials into these systems is essential for their longevity and effectiveness in challenging environments.

Frequently Asked Questions

What Materials Are Used in Self-Cleaning Brush Assemblies?

You’ll find that self-cleaning brush assemblies typically use durable materials like stainless steel or nylon for the brush components, ensuring longevity and resistance to corrosion. The material composition is chosen for its strength and flexibility, aiding effective cleaning. The cleaning mechanisms often include integrated scrapers or rotating brushes that remove debris, while the frame and other parts are made from corrosion-resistant plastics or metals to withstand harsh dock environments.

How Often Should Cleaning Maintenance Be Performed?

You should perform maintenance on your self-cleaning brush assemblies at least once a week, or more often if you’re dealing with heavy debris or harsh conditions. Think of your cleaning schedule as a superhero’s routine—regular, powerful, and unstoppable—ensuring peak performance. Ignoring cleaning frequency can turn your dock into a debris battlefield. Stay vigilant, stick to your maintenance schedule, and keep your self-cleaning system working like a well-oiled machine!

Are Self-Cleaning Brushes Suitable for All Dock Types?

Self-cleaning brushes are suitable for most dock types, but you should verify dock compatibility first. They work well in environments with regular debris, reducing cleaning frequency. If your dock experiences heavy buildup or specific conditions, you might need to adjust cleaning schedules or consider additional cleaning methods. Overall, these brushes help maintain dock cleanliness efficiently, but always confirm they suit your dock’s design and your maintenance needs.

How Do Environmental Factors Affect Brush Longevity?

Ironically, harsh weather actually extends your brush’s life—if only. Environmental factors like saltwater, humidity, and extreme temperatures wear down the brush faster, reducing its durability. You’ll want to look for corrosion resistance and environmental durability in your self-cleaning brush assembly. Otherwise, you risk frequent replacements, especially in corrosive environments. Proper material choices help your brush withstand these elements, ensuring longer-lasting performance despite Mother Nature’s best efforts to undermine it.

What Safety Features Are Integrated Into These Assemblies?

You’ll find safety sensors integrated into self-cleaning brush assemblies to monitor for obstacles or malfunctions, guaranteeing safe operation. Emergency stops are also included, allowing you to quickly halt the system if needed. These safety features help prevent accidents and equipment damage, giving you peace of mind during dock operations. Regularly checking sensors and emergency stop functionality ensures everything remains in excellent condition and safe for all users.

Conclusion

Self-cleaning brush assemblies keep docks running smoothly, much like a well-oiled machine. They automatically remove debris and prevent buildup, saving you time and effort. Think of them as a vigilant guardian, tirelessly working behind the scenes to guarantee everything stays clean and functional. With these innovative systems, you won’t have to worry about constant maintenance—just enjoy a seamless, efficient dock experience that works as effortlessly as a breeze on a sunny day.